Guidebook - Overview

What does Antelope do ??

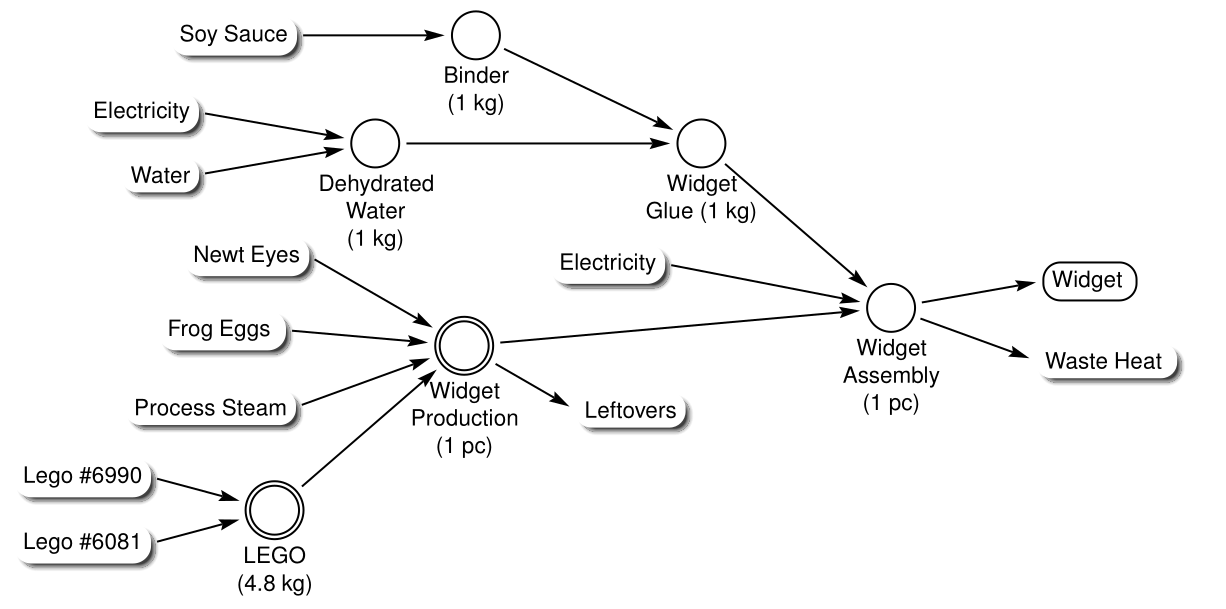

Antelope structures your life cycle inventory model as a collection of “fragments”, which represent exchanges of material flows that can be observed in real life. [flows elsewhere] Each fragment represents a material flow that occurs in the system being modeled.

These fragments are linked together to form tree structures, called “spanners” (as in spanning tree). Each spanner is defined by its reference flow.

A spanner is a formal definition of a gate-to-gate LCA system, in the sense that every node is in the system boundary, and everything that is not an observed flow is not in the system. Two practitioners can look at the model and agree on what’s in it.

These spanners form the modeling elements of the Antelope environment, and they can be linked together, shared, and reused.

Structuring the model

The task of modeling is itself irreducible- it must be performed by a person (or some other agent) who is familiar with the system. The graph structure of the spanner records that work.

If the flow is a material, say a product that a factory is shipping, the modeler can trace it physically along its journey through the facility, observing what happens to it in reverse order. As long as the modeler can obtain credible information about individual exchanges, the observed exchanges are part of the model “foreground.” As soon as a flow is no longer observable, it leaves the foreground system boundary and enters the “background.” This does not necessarily mean the flow goes “far away”- it simply is no longer being observed.

The modeler can take advantage of selective observation to design re-usable models. Any flow whose target is not observed becomes a “cutoff.” Cutoff flows can be linked later on during modeling to nodes that haven’t yet been specified. If a modeler embeds one spanner as a subcomponent of a larger models, then the cutoff flows can get linked to exchanges contained in that larger model. Thus the same spanner can generate different life cycle models by being re-used in different contexts.

Take truck transportation. It is very common for LCA modelers to

The modeler can link observations based on their vantage point. Imagine a machine on a factory floor it has a reference flow and a collection of child flows that can each be observed rom the machine’s vantage point. Those flows, in turn, imply other nodes, the “partners” to the exchange. The modeler can follow each flow in turn to its partner node, and make a new set of observations.

Each node of the tree can be quantity-conserving, allowing the modeler to enforce physical consistency.

Nodes can be built in small pieces and linked together to implement a variety of design strategies.

[ need a visual ]